Vario-X IPC Solution – Open for the future

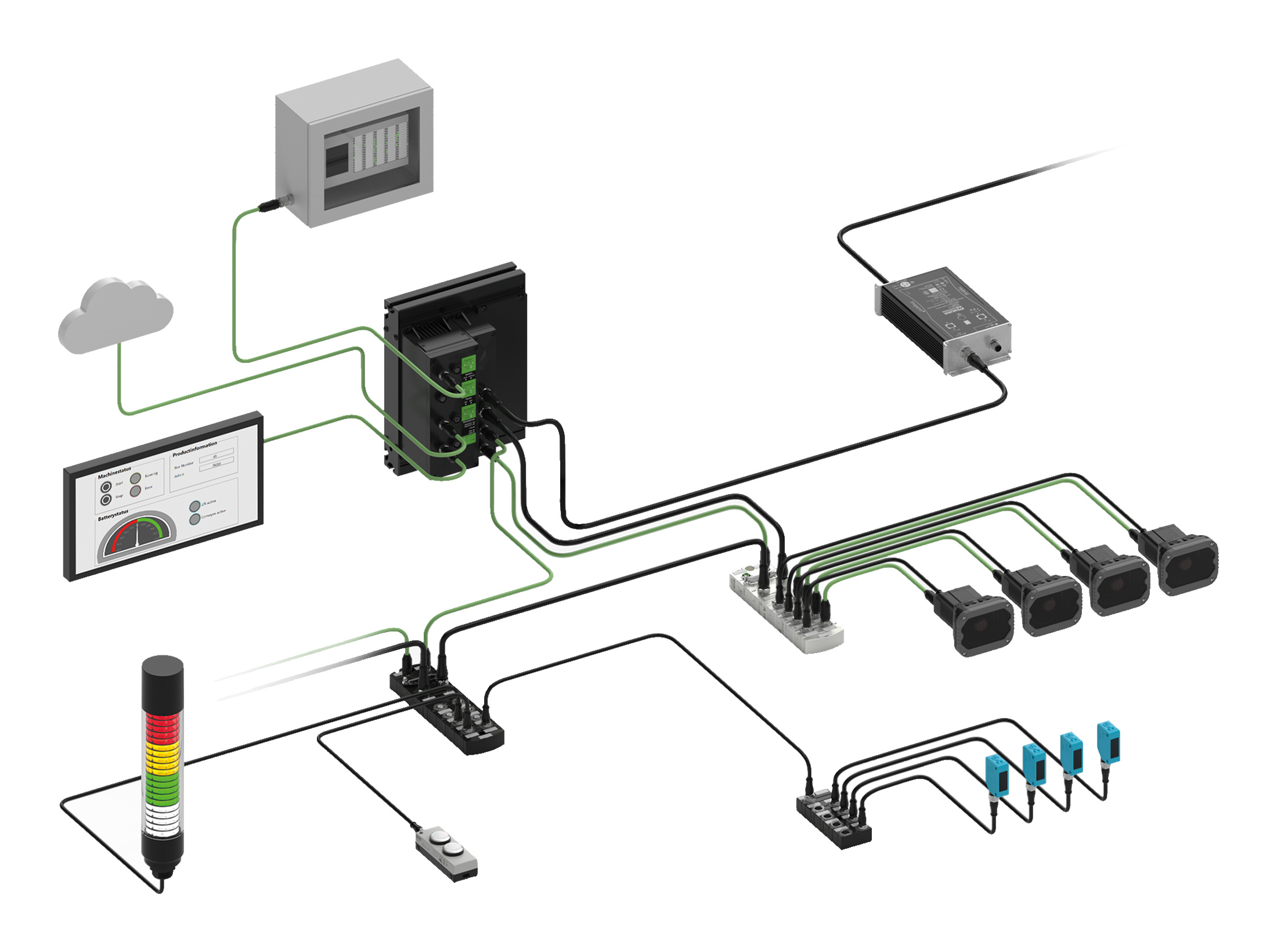

Our control solution combines the best of IPC and CODESYS PLC to create an open and future-oriented decentralized automation platform. By supporting all common network and communication protocols, we open the doors to a new era of industrial automation where flexibility and future-proofing are key. Our IPC solution is the heart of a decentralized installation solution that not only meets today's requirements, but is also ready for the challenges of tomorrow.

Decentralized automation

Murrelektronik's decentralized philosophy optimizes automation technology with advanced concepts that reduce installation effort and costs while increasing system efficiency.

Benefits of a decentralized system solution

- Less wiring: fast, error-free installation

- Pluggable solution: simple, seamless and scalable

- Compact and space-saving: optimal use of space

- Say goodbye to paperwork: Simplify documentation

- Relieve professionals: More time for essential tasks

- Flexibly scalable: future-proof through modularization

- Seamless integration: easily connect to cloud and network systems

Revolutionize your automation technology.

>> Arrange appointment now

Edge Gateway functionality

The Vario-X controller goes beyond the functions of a traditional PLC by also acting as an edge gateway. This makes it a key component for modern IoT and Industry 4.0 applications by building a bridge between local sensors and globally accessible cloud services. This bridge functionality not only facilitates the connection between different networks and systems, but also optimizes data processing and communication for industrial automation purposes.

Machine 1 - Machine x

The IPC operates as a control and data collection unit in the direct area of the machine or as an EDGE gateway. When used directly on the machine, the IPC avoids the need for a complex control cabinet thanks to its IP65 protection rating. As an EDGE gateway, the IPC processes data locally before it is transmitted filtered to the cloud, resulting in faster response times and increased reliability.

App

Access real-time data and machine status via an app, either via the cloud or direct VPN access, machines and systems can be flexibly monitored and controlled from any location.

Cloud

By transferring data to a cloud platform, real-time data can be used efficiently, both for analyses and for apps in the cloud.

Security

End-to-end encryption in IoT communications provides reliable protection and ensures the privacy and integrity of data.

Capabilities of the Vario-X IPC Solution

Discover the power of the Vario-X IPC Solution

From data storage and HMI visualization to edge computing and cloud connectivity, the Vario-X controller offers seamless integration from the sensor to the cloud. Want to optimize your industrial automation?

Our programming services offer a full range of support, from consultancy to complete programming.

Our dedicated helpdesk team is available 24/7 to answer your questions and provide technical support to keep your business running smoothly.

Our remote service enables us to quickly access your systems when questions or problems arise. We can diagnose the situation immediately and offer effective solutions to reduce downtime and increase your productivity.

Our qualified team of engineers are ready to provide on-site support when you need it. From installation to maintenance, we are there for you.

CPU: Intel Atom x6414RE (4 x 1,5 Ghz; 1,5 MB cache)

RAM: 8 GB LPDDR4x with up to 4267 MT/s

Flash: 32 GB eMMC 5.1

Memory: 128 GB SSD (optional up to 1 TB)

Memory card: 16 GB micro SD card

Operating system: Linux Yocto

Software: CODESYS V3 PLC runtime

Integrated sensors: temperature, humidity, vibration

Protection class: IP65

- 2x Industrial Ethernet Ports

- 2x Additional Industrial Ethernet Ports

- 2x Gigabit Ethernet Ports

- 1x HMI Port (Ethernet + 24 VDC), 1x Serial Interface

- 1x 24 VDC Input

- 1x 24 VDC Output

- 1x EtherCAT Port

- 1x Gigabit Ethernet Port

- Distribution of protective extra-low voltage, fieldbus and Gigabit Ethernet to the mounted devices.

- Integrated machine construction profiles for mounting and using accessories.

Industrial Automation with Murrelektronik

The innovative Vario-X controller is a key component of our vision to revolutionize industrial automation. Designed for the dynamic challenges of Industry 4.0, it combines traditional control functions with state-of-the-art edge computing, creating a solid foundation for future-proof and efficient operations. Its compatibility with a wide range of network and communication protocols makes it a highly adaptable solution that can be used in many automation scenarios. As your partner for automation technology, we support you with a comprehensive range of services to ensure that your requirements are efficiently met in every phase of your operation. Rely on Murrelektronik to optimize your automation processes today and in the future.

Now it's your turn…

Be open to the future of automation. Contact us today to find out how your production can benefit from the power and flexibility of Vario-X.